Glycidyl Neodecanoate (Novaester GND10)

NAME: Glycidyl Neodecanoate

GRADE: Novaester® GND10

SYNONYMS: 2,3-Epoxypropyl Neodecanoate

FORMULA: C₁₃H₂₄O₃

M.W.: 228.33

CAS NO.: 26761-45-5

EC NO.: 247-979-2

HS CODE: 2915.9000

NAME: Glycidyl Neodecanoate

GRADE: Novaester® GND10

SYNONYMS: 2,3-Epoxypropyl Neodecanoate

FORMULA: C₁₃H₂₄O₃

M.W.: 228.33

CAS NO.: 26761-45-5

EC NO.: 247-979-2

HS CODE: 2915.9000

![]()

Glycidyl Neodecanoate (CAS No. 26761-45-5), also called 2,3-Epoxypropyl Neodecanoate or GND, is synthesized from neodecanoic acid and epichlorohydrin. Our grade is called Novaester GND10 which had been exported to many countries.

Glycidyl Neodecanoate (CAS No. 26761-45-5), also called 2,3-Epoxypropyl Neodecanoate or GND, is synthesized from neodecanoic acid and epichlorohydrin. Our grade is called Novaester GND10 which had been exported to many countries.

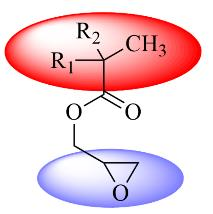

It's a synthetic saturated monocarboxylic acid mixture of highly branched isomers. The structure may be represented as:

Both R1 and R2 are alkyl withtotal7carbon atoms. The tertiary carbon structure has large steric hindrance, which is similar to umbrella structure. Therefore, it has good hydrophobicity, acid and alkali resistance, and UV resistance. The active epoxy group is easy to react with carboxyl group, amino group and hydroxyl group. The hydroxyl group formed after ring opening can be used for crosslinking.

It is a high-performance specialty chemical widely used in coatings, adhesives, and resin modification, valued for its low volatility, light color, low odor, and ultra-low organic chlorine content (<0.02%).

![]()

| Specification | Standard | Test Method |

| Epoxy Group Content | 4100-4300 mmol/kg | Perchloric Acid Titration |

| Epoxy Molar Mass | 232.5-244 g/mol | ----- |

| Color Pt/Co | ≤35 | ASTM D1209 |

| Appearance | Clear Liquid | Visual |

| Water | ≤0.1% m/m | ASTM E203 |

| Viscosity at 25℃ | 7.12 mPa.s | ASTM D445 |

| Viscosity at 100℃ | 1.30 mPa.s | ASTM D445 |

| Viscosity at 125℃ | 0.94 mPa.s | ASTM D445 |

| Viscosity at 150℃ | 0.72 mPa.s | ASTM D445 |

| Density at 15-40℃ | 0.95-0.97 g/ml | ASTM D4052 |

| Vapour Pressure at 37.8℃ | 0.9 kPa | ASTM D323 |

| Specific Heat at 25℃ | 1.733 kj/kg.℃ | DSC |

| Boiling Range at 5%-90% (v/v) 101.3 kPa | 251-278 ℃ | ASTM D86 |

| Flash Point (PMC) | 126 ℃ | ASTM D93 |

| Solidification Point | ≤-60℃ | ASTM D97 |

| Technical Data Sheet (TDS) | If needed, please email to sales@novacid.com | |

| Safety Data Sheet (SDS) | If needed, please email to sales@novacid.com | |

![]()

Glycidyl neodecanoatemakes it a unique modifier of coating resin. The epoxy group has high reactivity and can react with carboxyl, amino and hydroxyl groups. The reactivity of epoxy group enables it to be introduced into acrylic resin, polyester and alkyd resin at lower temperature with few side reactions. The polyester prepared by this method meets the design requirements of narrow molecular weight distribution and low viscosity. Branched chain fatty acid structure provides hydrolysis stability, weatherability and UV resistance of the resin. The suspended tertiary carbon structure can also reduce the viscosity of the modified resin and improve the wettability and plasticization of the pigment.

Typical applications include:

(1) Acrylic polyol resin

(2) High solid resin and water borne coatings

(3) Active diluent for epoxy resin

(4) Automotive topcoats, intermediate paints, primers, varnishes and touch up paints

(5) On heavy duty anticorrosive coatings for ships and bridges

![]()

- Packaging Options

- Industrial Grade: 200L net weight per steel-plastic drum

- Storage Requirements

Store in a cool, dry, and well-ventilated warehouse, away from direct sunlight, heat sources, and incompatible substances (e.g., strong oxidizers, bases).

Shelf life is 24 months when stored under recommended conditions.

- Handling Precautions

Wear protective gloves and goggles during operation to avoid direct contact with skin and eyes. In case of accidental contact, rinse thoroughly with plenty of water and seek medical advice if necessary.