Neodecanoic Acid (Novacid NEO10)

NAME: Neodecanoic Acid

GRADE: Novacid™ NEO10

SYNONYMS: Versatic acid 10

FORMULA: C₁₀H₂₀O₂

M.W.: 172.26

CAS NO.: 26896-20-8

EC NO.: 248-093-9

HS CODE: 2915.9000

NAME: Neodecanoic Acid

GRADE: Novacid™ NEO10

SYNONYMS: Versatic acid 10

FORMULA: C₁₀H₂₀O₂

M.W.: 172.26

CAS NO.: 26896-20-8

EC NO.: 248-093-9

HS CODE: 2915.9000

![]()

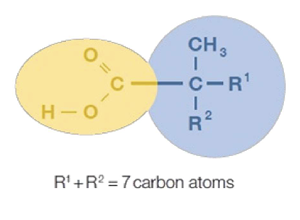

Neodecanoic Acid (CAS No. 26896-20-8), also known as Novacid Neo10 or Versatic Acid 10, is a synthetic carboxylic acid with a highly branched-C10 tertiary carboxylic acid. it is not a single compound but a mixture of isomers, each sharing the general formula C₁₀H₂₀O₂. The key to understanding its behavior lies in its branched-chain structure. This is unlike straight-chain carboxylic acids, impacting its reactivity and physical properties. The branched structure is responsible for its relatively low vapor pressure, a crucial factor in its industrial appeal. Lower vapor pressure translates to easier handling, reduced risk of volatile emissions, and enhanced safety in industrial settings. Its unique combination of properties—such as hydrophobicity, UV stability, and high reactivity—makes it a valuable component in adhesives, lubricants, coatings, and more. Novacid NEO10 can be replacement of Versatic Acid 10. This branched structure also influences the acid's behavior in reactions. Its behavior is similar to that of trialkyl acetic acids, a class known for their steric hindrance related to its branched alkyl groups. This steric hindrance might affect reaction rates and selectivity in certain chemical processes, making NDA suitable for specific synthetic pathways where precise control is necessary. (R1 and R2 are alkyl groups. Novacid NEO10 contains a total of 10 Carbon atoms. Novacid NEO10 is a water-like clear product hat is liquid at ambient temperature.)

This branched structure also influences the acid's behavior in reactions. Its behavior is similar to that of trialkyl acetic acids, a class known for their steric hindrance related to its branched alkyl groups. This steric hindrance might affect reaction rates and selectivity in certain chemical processes, making NDA suitable for specific synthetic pathways where precise control is necessary. (R1 and R2 are alkyl groups. Novacid NEO10 contains a total of 10 Carbon atoms. Novacid NEO10 is a water-like clear product hat is liquid at ambient temperature.)

![]()

| Specification | Standard | Test Method |

| Acid Value | 320-330 mgKOH/g | ASTM D1980 |

| Apperance | Clear Liquid | Visual |

| Color Pt/Co | ≤100 | ASTM D1209 |

| Water | ≤0.1% m/m | ASTM E203 |

| Boiling Range at 760mm Hg | 270-280℃ | ASTM D1078 |

| Density at 20℃ | 0.91kg/L | ASTM D1298 |

| Flash Point (PMC) | 129℃ | ASTM D93 |

| Odour | Strong | ----- |

| Mscibility with water | Negligible | ----- |

| Freezing Point / Pour Point | ≤-30℃ | ASTM D97 |

| Purity | ≥90% | GC |

| Vapour Pressure at 20℃ | ≤0.02 kPa | ASTM D5191 |

| Viscosity at 20℃ | 45 mm2/s | ASTM D445 |

| Technical Data Sheet (TDS) | If needed, please email to sales@novacid.com | |

| Safety Data Sheet (SDS) | If needed, please email to sales@novacid.com | |

![]()

Novacid NEO10 is a key intermediate in the manufacture of a variety of products, which typically show excellent hydrolyic stabilliy and resistance to various chemical agents. This is due to the steric hindrance created by the highly branched Versatic structure combined with the tertiary nature of its alpha-carbon atom. This is especially demonstrated in comparison with its linear and secondary-C10 equivalents.

Novacid NEO10 can be used in its acid form, but for many applications the product is typically first converted into an acid chloride or metal salt. The acid chloride is produced by reaction with, for exampie, phosgene or PClʒ and is used in the production of peroxides for polymer production.Metal salts,e.g. Cobalt, Copper or Zinc salts of Novacid NEO10 are used in applications such as tire adhesives, paint driers, PVC heat stabilisers, chemical processing catalysts, unsaturated polyester cure catalysts, wood preservatives and fuel additives. Additionally, Novacid NEO10 is a very effective metal extraction agent that is particularly suitable for Nickel. The acid can also be used as corrosion inhibitor in synthetic lubricants.

1. Tire Adhesion Promoter

Neodecanoic Acid plays a crucial role in enhancing the safety and performance of radial tires. Its cobalt salt derivatives improve adhesion and durability in high-stress conditions.

· Superior Adhesion: Provides strong initial adhesion between rubber and brass-coated steel cords.

· High Durability: Maintains adhesion under extreme temperatures and humidity.

· Enhanced Safety Profile: Contributes to radial tire reliability and performance.

· Stable and Consistent: Synthetic production ensures high product quality.

· Commercial Benefits: Cobalt versatate derivatives derived from Neodecanoic Acid deliver up to 23% cobalt content per molecule.

2. Lubricants and Corrosion Inhibitors

Neodecanoic Acid is widely used in lubricants and metalworking fluids due to its corrosion-inhibiting properties and ability to act as a surfactant.

- Corrosion Inhibitor Properties:

· Iron Corrosion Protection: Metal versatate salts form a protective layer on metal surfaces, ideal for antifreeze and engine coolants.

· Oil/Water Phase Coupling: Ammonium versatates enhance coupling between oil and water phases, making them effective surfactants for metalworking fluids and asphalt-based coatings.

- Metalworking Fluid Benefits:

· Better Performance: The highly branched structure provides superior corrosion inhibition compared to linear acids like sebacic and azelaic acids.

· Long-Term Stability: Maintains clear solutions and stable mixtures by dispersing alkanol amines and metal hydroxides.

· Ease of Handling: As a liquid, Neodecanoic Acid dissolves easily in amino alcohol/water solutions without requiring heating.

These qualities make Neodecanoic Acid a preferred ingredient in antifreeze, lubricants, and metalworking fluids, ensuring both efficiency and cost-effectiveness.

3. Coatings and Adhesives

Neodecanoic Acid’s properties make it ideal for coatings and adhesives, where durability and stability are crucial.

· UV and Thermal Stability: Protects coatings from degradation, ensuring long-term performance in outdoor environments.

· Pigment Wetting: Improves dispersion in paints and coatings.

· Adhesion Promotion: Enhances bonding strength, especially in challenging applications like brass-coated steel cords in tires.

Its ability to combine hydrophobicity with reactivity ensures that products maintain their performance even under harsh conditions.

4. Industrial Applications

Neodecanoic Acid is also used in a variety of niche applications, including:

· Asphalt-Based Coatings: Improves adhesion and water repellency.

· Metal Extraction: Facilitates efficient extraction of metal ions due to its amphiphilic structure.

· Plastics and Polymers: Acts as a viscosity modifier and stabilizer in formulations.

![]()

- Packaging Options

- Industrial Grade: 200L net weight per steel-plastic drum

- Storage Requirements

Store in a cool, dry, and well-ventilated warehouse, away from direct sunlight, heat sources, and incompatible substances (e.g., strong oxidizers, bases).

Shelf life is 12 months when stored under recommended conditions.

- Handling Precautions

Wear protective gloves and goggles during operation to avoid direct contact with skin and eyes. In case of accidental contact, rinse thoroughly with plenty of water and seek medical advice if necessary.